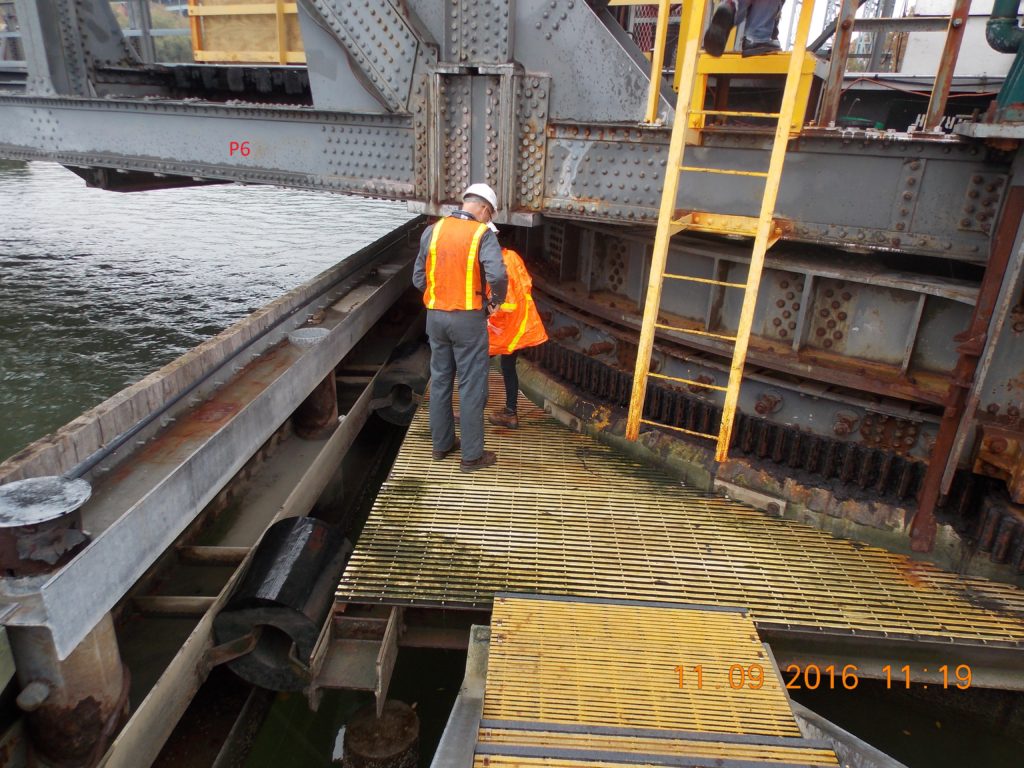

Superstorm Sandy damaged Spuyten Duyvil Bridge’s mechanical and electrical systems with high levels of loads and debris. As a subconsultant to Hardesty & Hanover, KC was part of the structural and mechanical team performing an in-depth inspection of the existing structure, platforms, and fender protection of this mechanical bridge. KC also provided the structural steel details for the repair of the damaged steel members and access platforms.

In addition, KC provided surveying services, including the precise location of 64 tapered rollers with the bridge closed, open, and in several partially opened positions; precise location of the bridge center of pivot with the bridge open, closed, and in several partially opened positions, which required establishing fixed points on the bridge to survey and then measuring and calculating the actual bridge pivot center, or measuring and precisely marking the center pivot of the bridge at the deck level and then surveying that as the bridge rotates; track alignment from abutment to abutment; and general bridge survey information, including key elevations.

This project repaired the bridge into good working condition, allowing trains to run over and boats to successfully navigate around this crucial bridge.