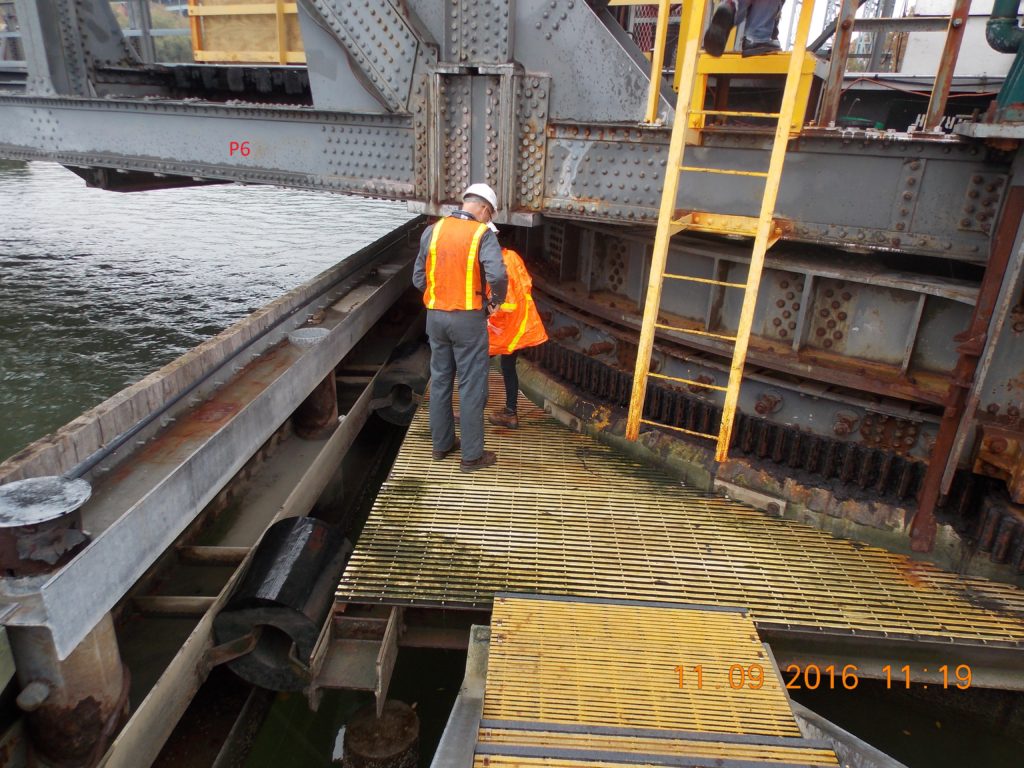

KC is happy to announce that the $365.7M Kew Gardens Interchange Infrastructure and Operational Improvement at Grand Central Parkway design-build project, for which we served as major design subconsultant and Quality Manager on the Halmar International LLC team, was awarded the 2023 ENR Award for Best Project Highway / Bridge. KC was recognized for our efforts as civil engineer on this pursuit, where we provided structural design of three new bridges, retaining walls, overhead sign and ITS structures, and a shared-use path; utility design of water mains, combined sewers, and electrical systems; NYCDEP water regulator replacement and blow-off valve relocation design; Con Edison utility relocation design; development of the existing sewer condition report; temporary and permanent drainage, stormwater, and lighting design; landscape architecture design; and environmental permitting.

We worked closely with the lead contractor and designer to deliver long-term, cost-efficient infrastructure solutions that addressed operational deficiencies within the project limits. Our success is largely due to the contributions of our dedicated staff, who put in hours' worth of hard work to deliver our services to the highest degree of quality.

To learn more about this remarkable achievement and view the project award on ENR’s website, please click on the following link: https://www.enr.com/articles/57558-best-project-highway-bridge-kew-gardens-interchange-infrastructure-and-operational-improvements-at-grand-central-parkway