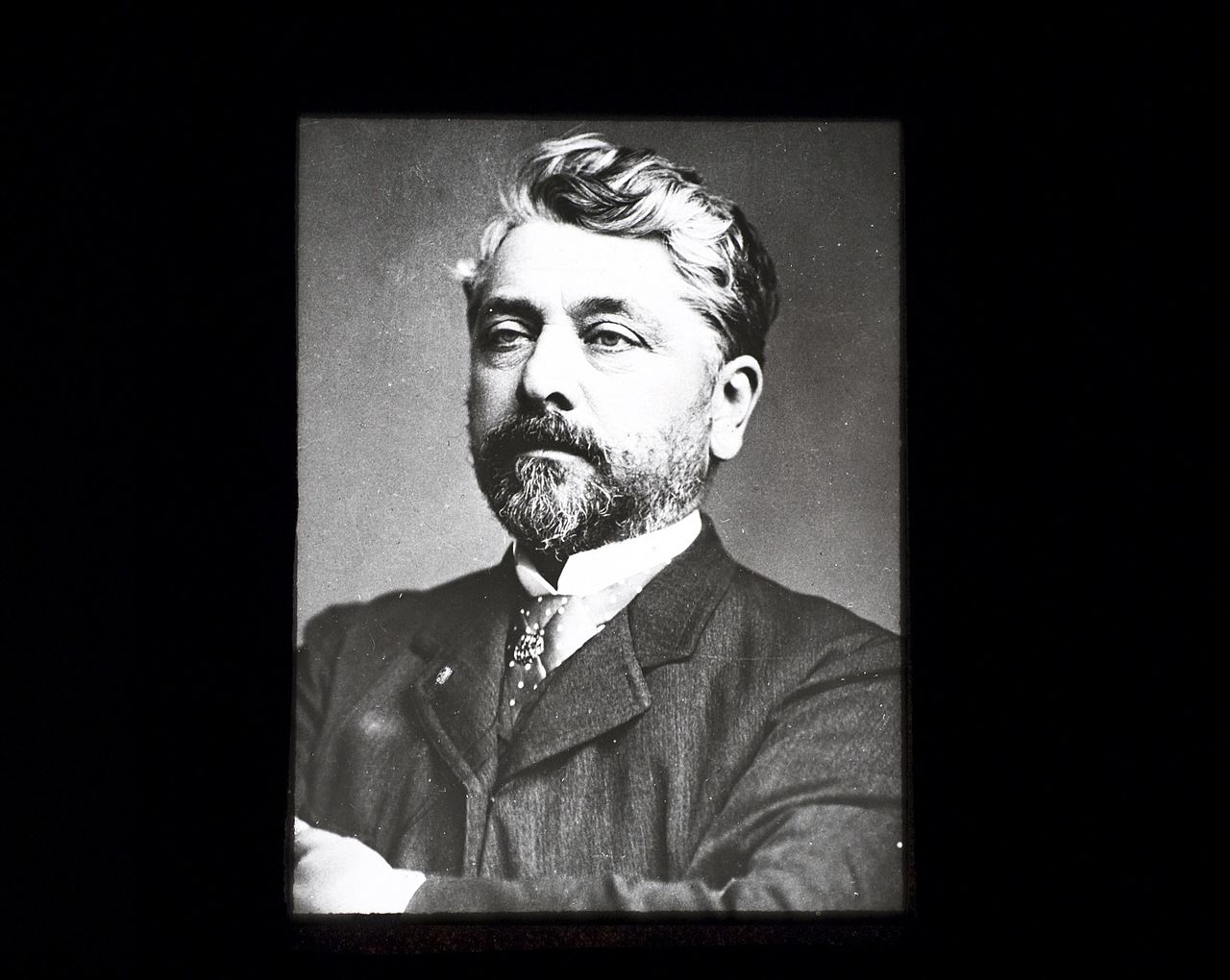

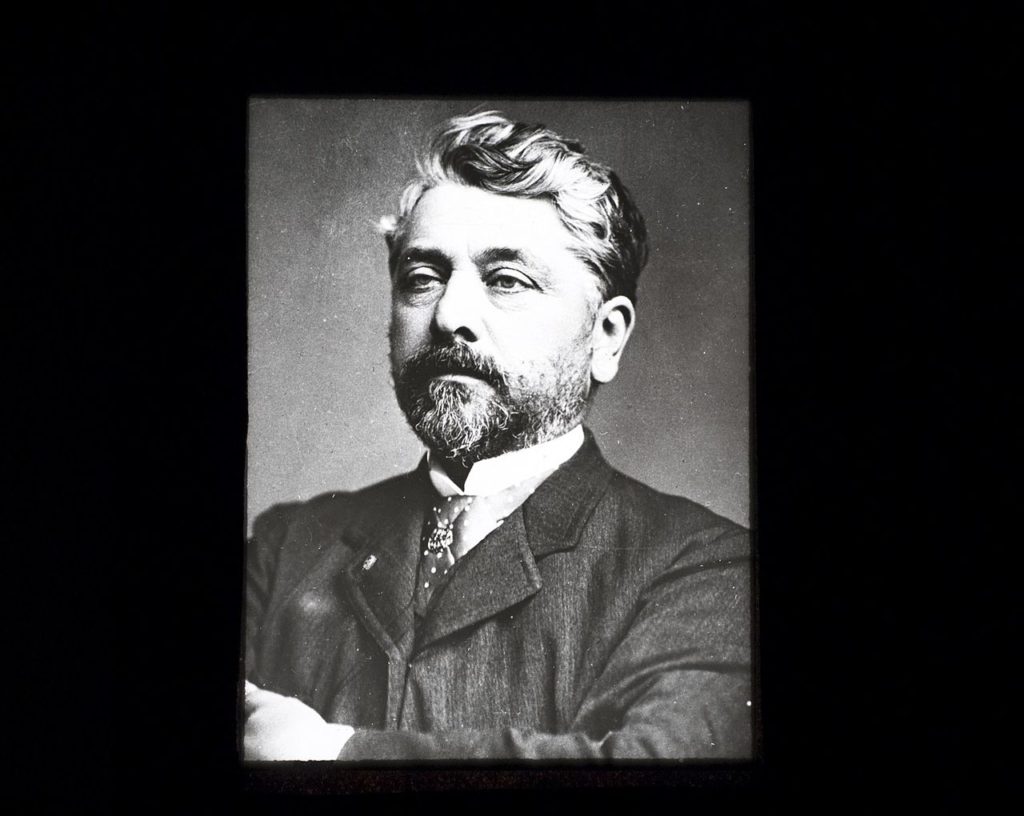

Gustave Eiffel (1832-1923): A renowned French civil engineer and architect, Gustave Eiffel is remembered as “the Magician of Iron.” Can you guess which famous iron structure this magician cast? Indeed, his masterpiece is the Eiffel Tower. During and after its construction, thinkers of the time criticized the tower’s ambitious design. Some even protested the tower, claiming Eiffel was blatantly disregarding the principles of physics to create an artistic form. However, his design for what was then to be the tallest tower in the world accounted for the real-world conditions that it would need to withstand:

Is it not true that the very conditions which give strength also conform to the hidden rules of harmony? … Now to what phenomenon did I have to give primary concern in designing the Tower? It was wind resistance. Well then! I hold that the curvature of the monument's four outer edges, which is as mathematical calculation dictated it should be … will give a great impression of strength and beauty, for it will reveal to the eyes of the observer the boldness of the design as a whole. – Gustave Eiffel

Thanks to both Eiffel’s genius and his boldness, the Eiffel Tower today enjoys a coveted spot on the list of the Seven Wonders of the World, and it remains a veritable global icon.

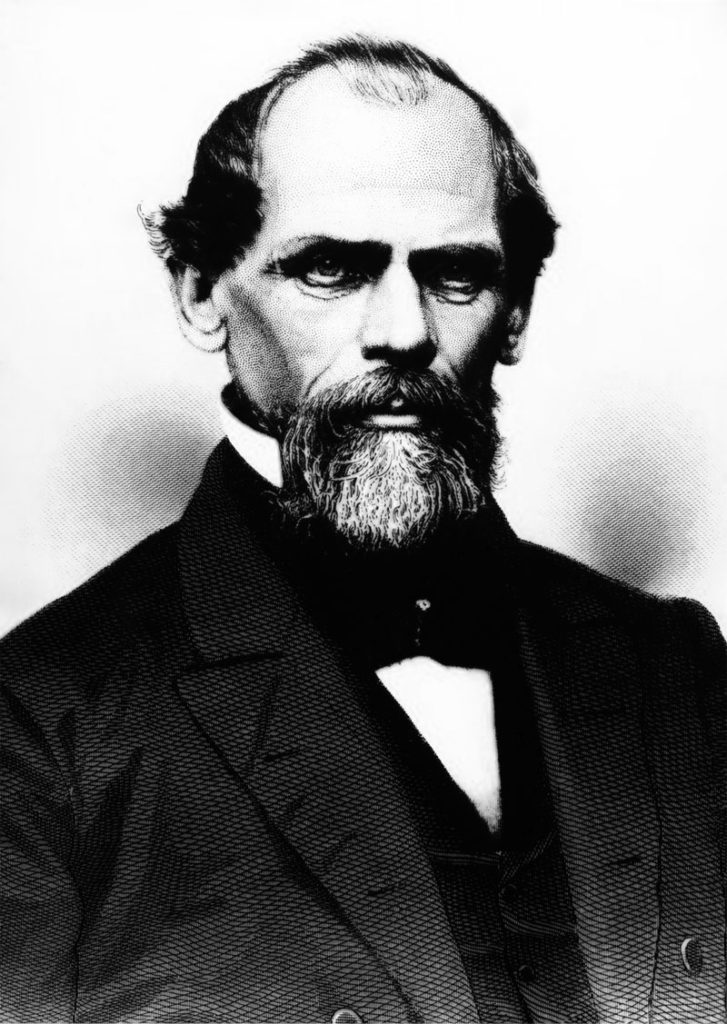

George Stephenson (1781-1848): George Stephenson revolutionized transportation and urban infrastructure by creating the world’s first public inter-city railway line that used steam locomotives. This British Engineer, often referred to as “The Father of Railways,” is also credited with devising the historic measurement of the rail gauge at four feet eight-and-a-half inches, which became the standard railway gauge measurement worldwide.

Isambard Kingdom Brunel (1806-1859): A celebrated experimenter and risk-taker, Isambard Kingdom Brunel was the man behind the Great Western Railway, the company that connected London to the west part of England. His unconventional thinking led him to many firsts: from being the first engineer to envision building a tunnel under a river to playing a key role in the development of the first propeller-driven iron ship.

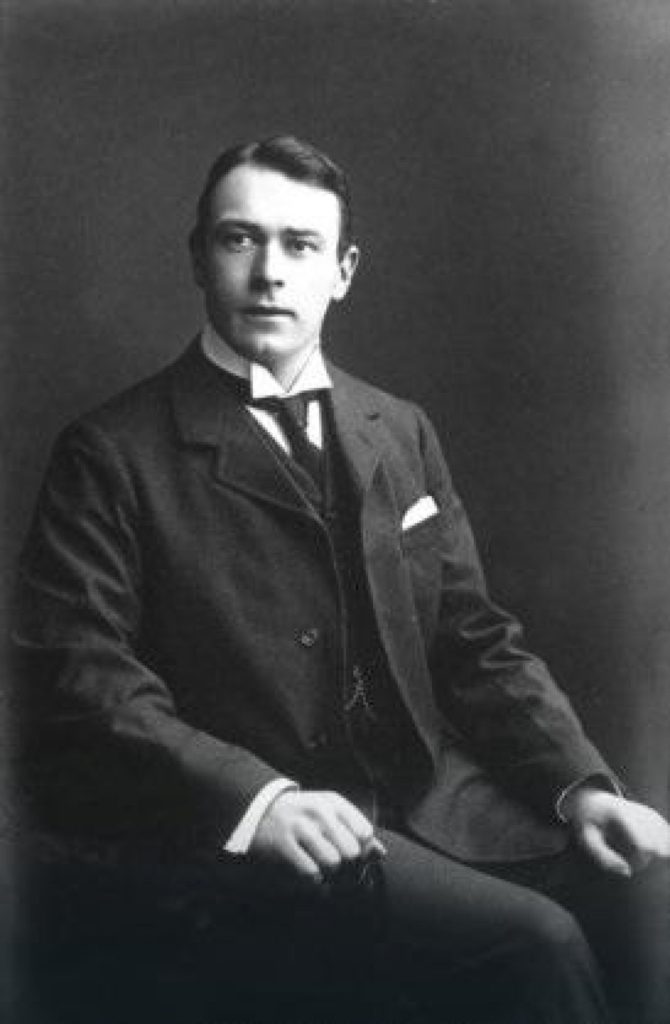

Thomas Andrews (1873-1912): Thomas Andrews was the principal architect for the infamous RMS Titanic. He was aboard the ship during its maiden—and only—voyage in 1912, and when the ship hit an iceberg, he calculated that it would sink within a few short hours. Survivors’ accounts tell of Andrews bravely alerting passengers of the imminent danger, urging women and children to board the severely limited number of lifeboats. Andrews was also said to have suggested more than twice the number of lifeboats the Titanic was given and a double hull and watertight bulkheads during planning and construction, suggestions that were rejected. He perished in the ship’s sinking, a harsh lesson in the consequences of industrial hubris, prioritizing profit over safety.

John Augustus Roebling (1806-1869): A Prussian immigrant renowned for his suspension bridge designs, John Augustus Roebling discovered a method of twisting iron together to create a “wire rope,” which he manufactured and used to construct durable suspension bridges. One of the most famous projects he designed was the Brooklyn Bridge. Unfortunately, he sustained an injury in an on-site accident that resulted in a fatal case of tetanus before the bridge could be completed.

Bonus! – Emily Warren Roebling (1843-1903) and Washington Roebling (1837-1926): Emily Warren Roebling broke down gender barriers while building the Brooklyn Bridge. Hailing from the Hudson Valley, she studied engineering in Europe alongside her husband Washington Roebling, the son of John Augustus Roebling. Washington took over as Chief Engineer following his father’s death, but he soon developed caisson disease and became too ill to work. Emily then stepped in as “the first woman field engineer.” She carried out many of Washington’s duties, overseeing construction until the bridge’s completion in 1883.