Did you know that 99.7% of Earth’s water supply is not usable by humans? This unusable supply includes not only saltwater but fresh water supplies from lakes and streams that often contain Cryptosporidium, E. coli, Hepatitis A, and Giardia intestinalis. The water we drink, from taps and bottles and fountains, goes through an extensive treatment process to rid itself of these harmful pathogens.

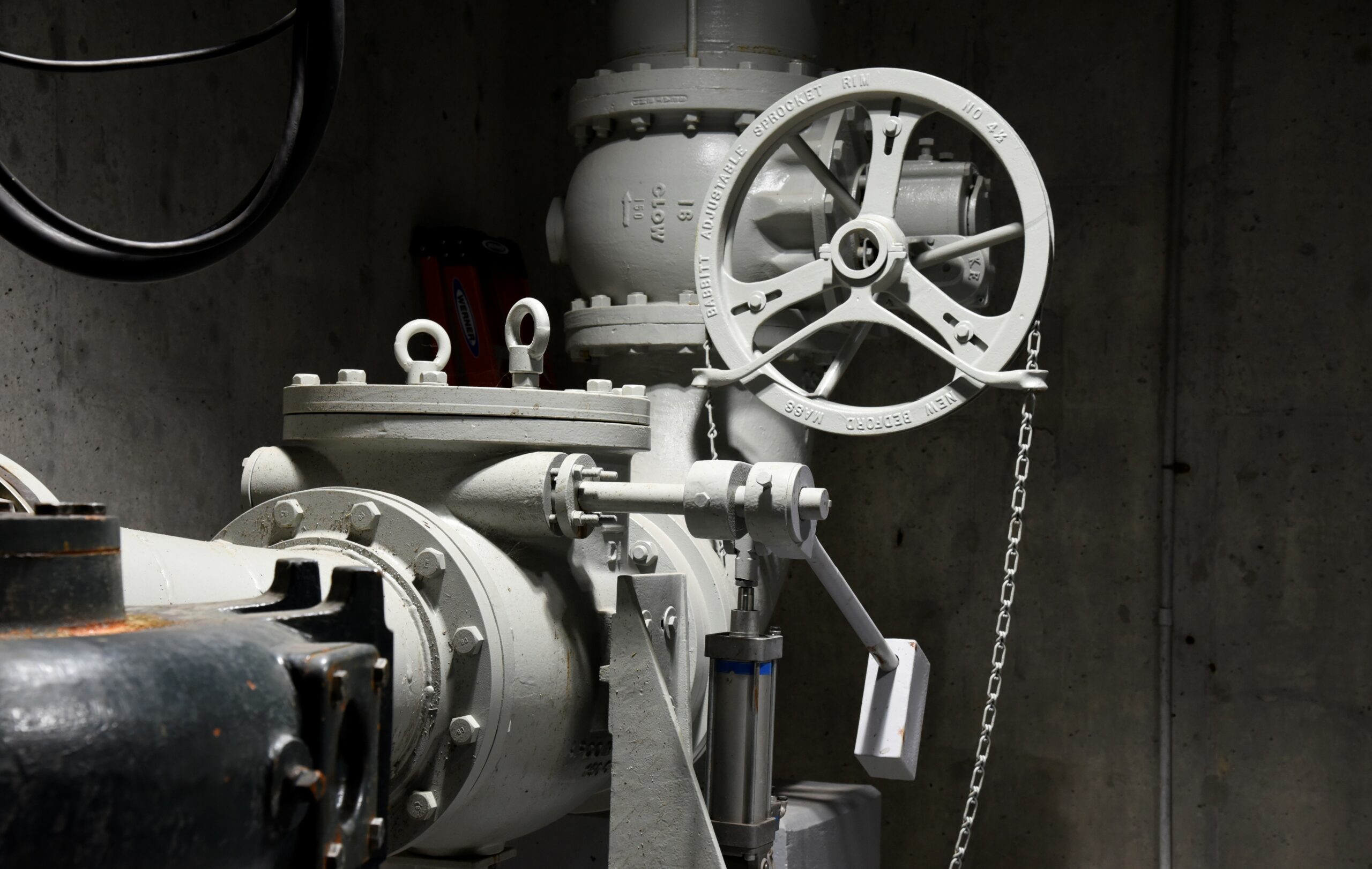

A water treatment plant serves its local community by sourcing its water from the surface, from lakes, streams, reservoirs, or from the ground, where water pools after seeping in from rain or snowfall. The plant is then tasked with disinfecting and purifying this “raw,” or untreated, water.

Below is a step-by-step look into how your water is treated:

The first step of the purification process is coagulation and flocculation: in this step, a coagulant, such as aluminum sulphate or iron salt, is added to the water to neutralize the negative charge of any dirt, parasite, or bacteria that might be present. This neutralization enlarges the harmful particles in preparation for the following step.

The second step is referred to as sedimentation, where the now enlarged dirt particles can more easily sink to the bottom of the water.

The third step is filtration, where the water is run through sand, gravel, or charcoal to weed out the enlarged dirt particles.

The fourth step is disinfection where a chemical such as chlorine or chloramine is added to the water to both kill any remaining parasites or bacteria and prevent the growth of new ones.

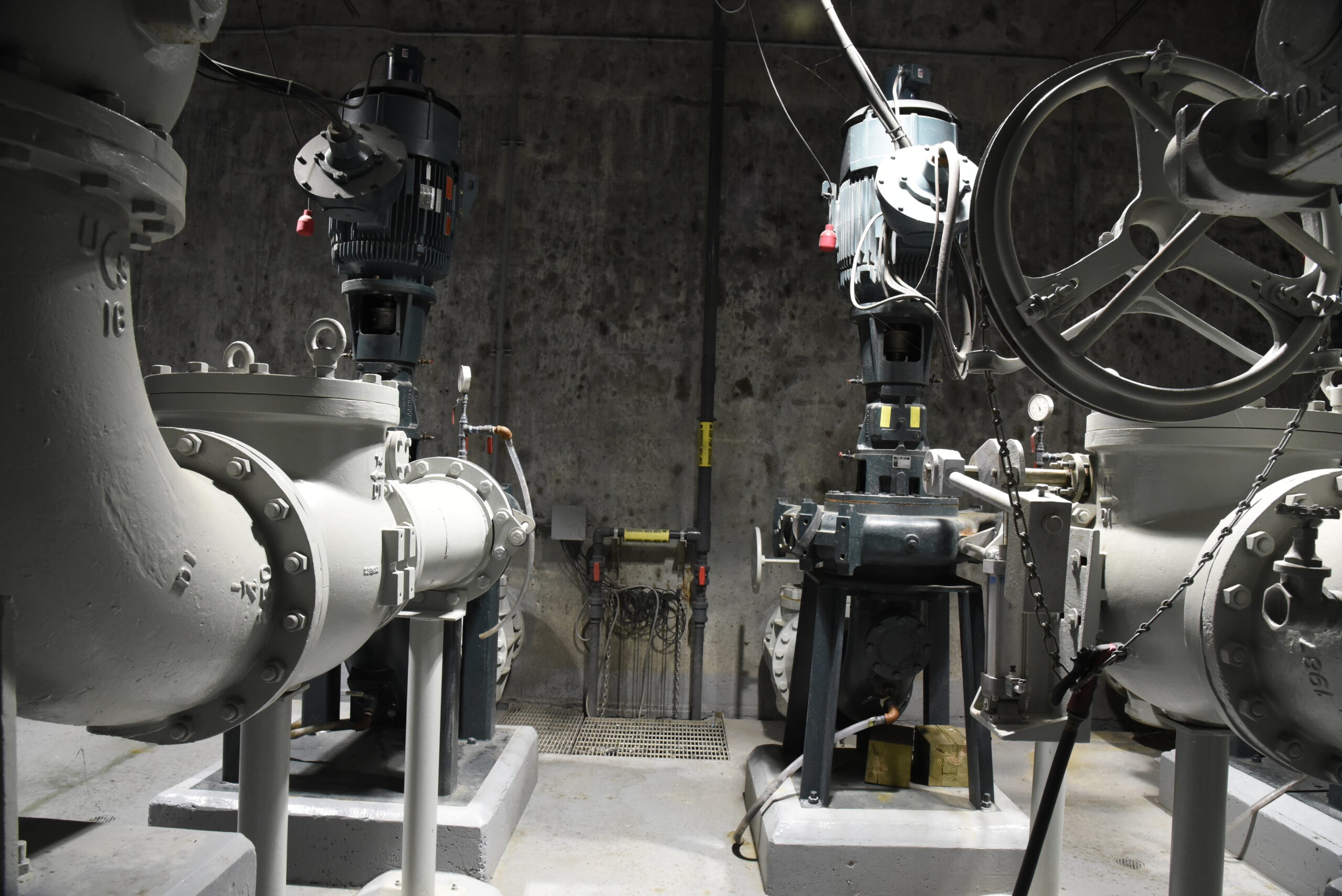

Finally, the purified water is stored in a water tower and, with plenty of gravity and pumps, is delivered into your home.

Want to find out more about the quality of your drinking water? Visit this site to access an annual drinking water quality report from your local water supplier.